CPM Ring die

Home > Mechanical spare parts > Ring die > CPM Ring die

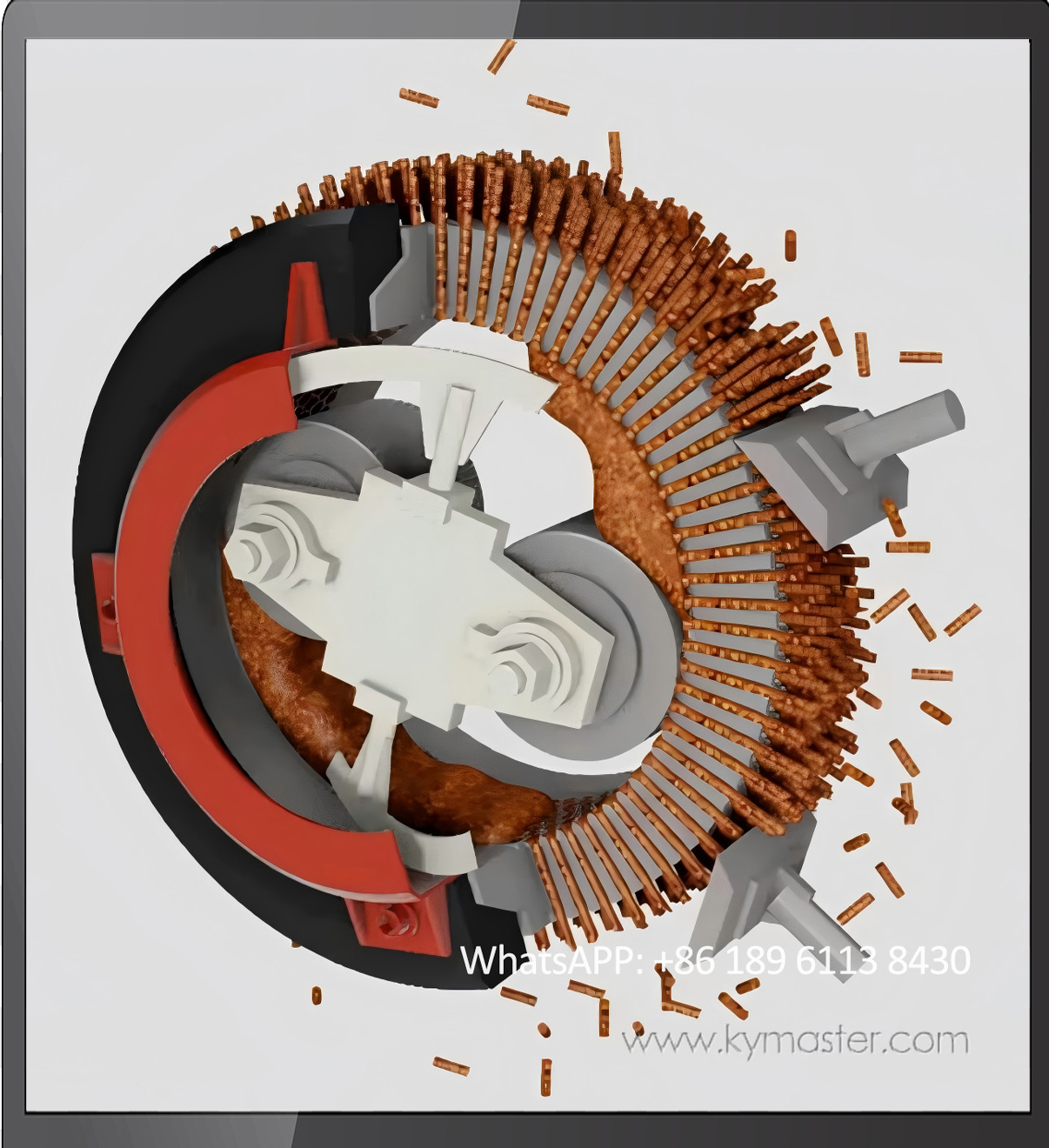

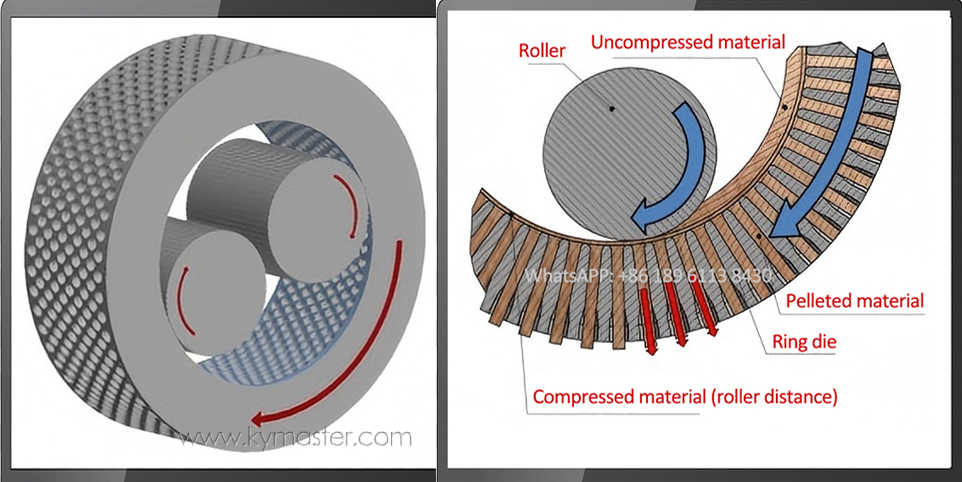

Ring die is one of the key parts of a pellet mill, which is wearing part and expensive. Its quality and durability determine the service life, production capacity and pellet quality, furthermore, directly affecting production costs.

The main failure of the ring die is due to worn-out die holes and inner surfaces (rendering it unusable), though cracking and clogging (preventing pellet extrusion) also occur in some cases.While the die's lifespan is largely determined by its material and manufacturing process. Additionally, for the same material and processing method, its life time is also influenced by factors such as raw material properties, processing parameters, and operational techniques.

Moreover, the smoothness of the die hole surface directly affects whether the ring die can discharge material properly during the initial trial pressing.

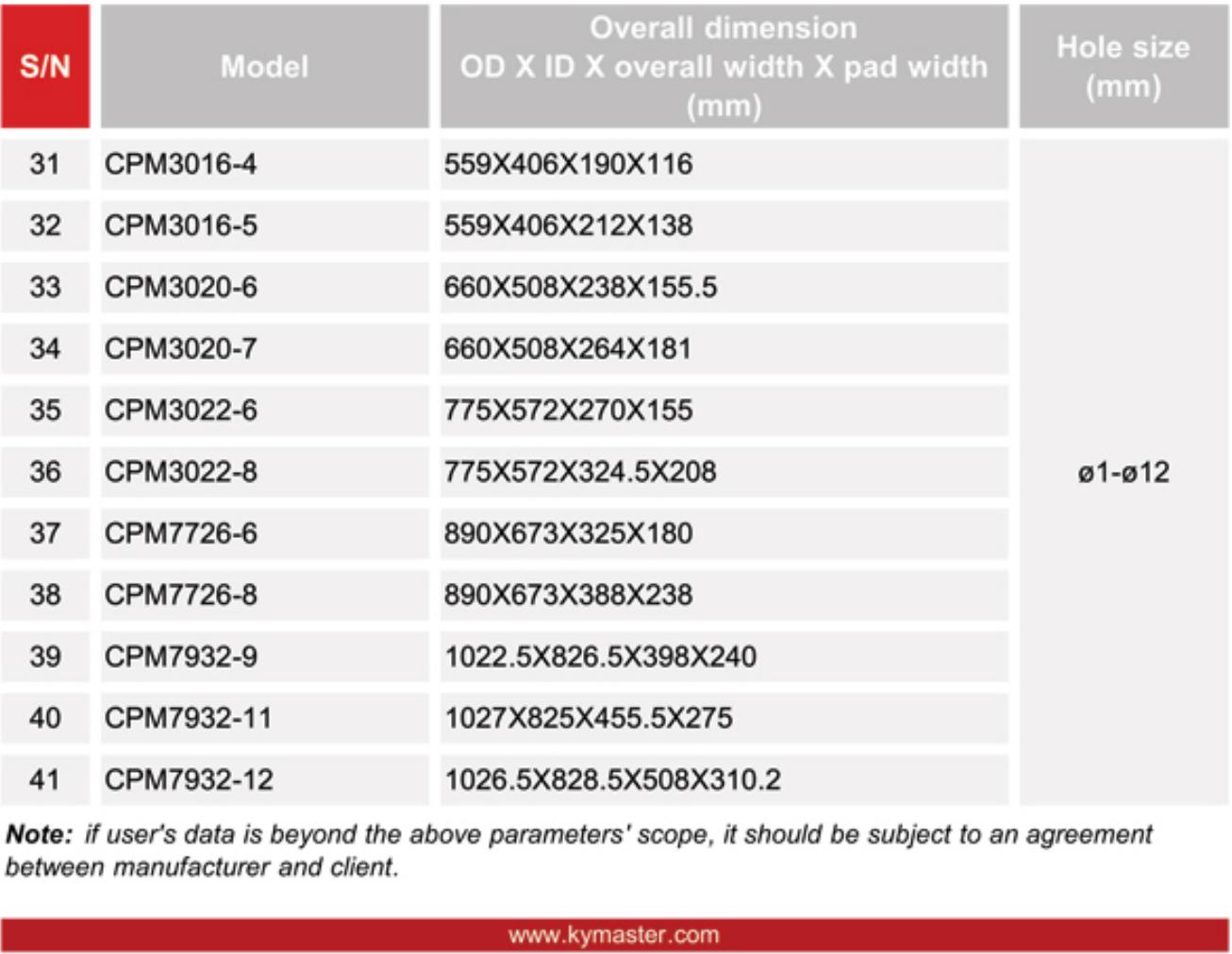

Our company supply dies with a ID up to 900mm, OD up to 1,440mm,hole diameters from 1.0mm to 30mm, compression rate is up to 25. We manufacture about 5000pcs dies every yearand customized pellet ring dies for different brands of pellet mill, learn more about our ring dies processing

1. Description of CPM Ring Die

Smooth die hole, nice appearance, large capacity, high quality, long life

1.1 Full automatic CNC ring die drilling machine ensure once-shaped die hole with smooth finish, nice feed outlook, high capacity.

1.2 Vacuum heat treatment technology for a better working life of pellet mill ring dies.

1.3 Rich ring die processing experience ensures the depth and opening ratio of the hole of ring die which can satisfy different requirements of poultry, livestock and aqua feed, thus improves the pelleting efficiency.

1.4 Quick discharge, high output and the production efficiency of the same size are much higher than ring dies of other brands.

1.5 Different types and hole diameters can be processed.

3. CPM pellet press ring die's technical parameters

Superior Wear Resistance, Smoother Operation – Upgrade to Our Ring Dies Today! Avaiable to CPM, Buhler, CPP, OGM, Zhengchang(SZLH/MZLH), Amandus Kahl, Muyang(MUZL), Yulong(XGJ), AWILA,PTN, Andritz Sprout, Matador, Paladin, Sogem, Van Arssen, Yemmak, Promill etc.

We can also customize for you according to your drawing.